The Optimum Mobile Workers Management System (Optimum MWMS) is designed to automate the activities of personnel performing maintenance and repair of equipment and facilities (MRO), as well as to manage processes in the field of the Industrial Internet of Things (IIoT).

The system of the FSA (Field Service Automation System) class provides automation of business processes related to planning and optimal distribution of work requests, as well as tracking the activities of mobile workers on the road. Operational data exchange is carried out via any wireless communication channels (cellular, satellite, special communication).

The Optimum MWMS is implemented on the Optimum technological platform and is included in the Unified Register of Russian Programs for Electronic Computers and Databases of the Ministry of Communications and Mass Media of the Russian Federation (No. 7782). Since 2019, it replaces the Optimum MMC solution (Mobile Monitoring and Service) in the CDC product line.

Optimum MWMS functionality

The Optimum MWMS consists of a server and a mobile parts.

The server part consists of a database, a synchronization server, a web application with authorized access, and other components. The users of the application are dispatchers, operators, foremen, analysts, contractors, heads of enterprises.

An example of task for equipment inspection.

Basic server side capabilities

- Work planning.

- Efficient distribution of tasks.

- Work scenarios.

- Accounting for work performance.

- Prompt transmission of data on the performance of work to the head office.

- Accounting for standards (for all operations, details, etc.).

- Accounting for the consumption of materials and spare parts.

- End-to-end location control, including linking to key operations.

- Accumulation and analysis of collected data.

- Advanced reporting.

- KPI management.

- Sensor monitoring (IIoT).

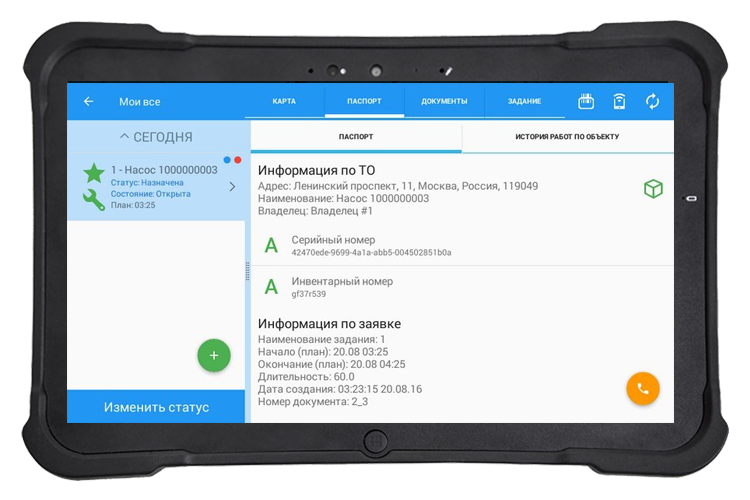

The mobile part is an application with authorized access based on Android, iOS, Windows, Aurora (ex-Sailfish Mobile OS Rus). Application users are repair and maintenance personnel (service engineers and technicians, electricians, emergency crews, trackmen, etc.).

An example of receiving a task on a mobile device.

Basic capabilities of the mobile part

- Working with scripts.

- Monitoring the execution of bypasses by RFID, NFC, QR codes on equipment.

- RFID, NFC, QR codes authorization on equipment to perform tasks.

- Transfer of task execution statuses / key operations to the system.

- Accounting for materials and spare parts (according to the norms, upon use, etc.).

- Photo and video recording of the results of work, defects and other operations.

- Convenient access to the necessary information (reference data, work history, documentation, instructions, etc.).

- Work offline and online.

- Creation of emergency and additional orders.

- Convenient interaction with the dispatcher.

- Using voice input (recognition and translation of speech to text).

An example of filling out the results of equipment inspection.

We believe that the implementation of the CDC solution at Aeroflot - Russian Airlines is economically justified. It made it possible to improve the quality of aircraft servicing, reduce mileage and downtime of equipment, and more efficiently distribute tasks to apron personnel.

Tasks

- Comprehensive long-term and operational planning of maintenance and repair.

- Quality control of planned and unscheduled works (Who? What? How? Where? And when exactly did it?).

- Justification of the cost / timing of work.

- Effective management of human and material resources in the face of time constraints and emergencies.

- Control of the use, consumption and write-off of tools, consumables and spare parts.

Relates solutions

Maintenance and Repair Automation